PRODUCT

PP Filament Spunbond Needle Punched Nonwoven Geotextile

PP filament spunbond needle punched nonwoven geotextile uses polypropylene as raw materials, is processed by spinning, airflow laying, needle punching and other processes

PP filament spunbond needle punched nonwoven geotextile uses polypropylene as raw materials, is processed by spinning, airflow laying, needle punching and other processes

♦Features

Polypropylene filament spunbond needle-punched geotextile has the advantages of high strength, strong puncture resistance, corrosion resistance, anti-microorganism, aging resistance, high temperature resistance, superior water permeability, filtration, soil retention and so on. Compared with polyester filament geotextile, its strength is higher, tear resistance and puncture resistance is stronger, especially acid and alkali resistance, can be in long-term contact with cement, fly ash, lime and other alkaline materials, can maintain stable performance in alkaline environment, no hydrolysis.

♦ Application

It is mainly used for high-speed rail ballastless track isolation layer, tunnel impermeable gasket layer, airport runway isolation layer, highway anti-cracking substrate, water conservancy project revetment bottom, landfill, emergency engineering foundation treatment, ecological slope protection and other engineering fields.

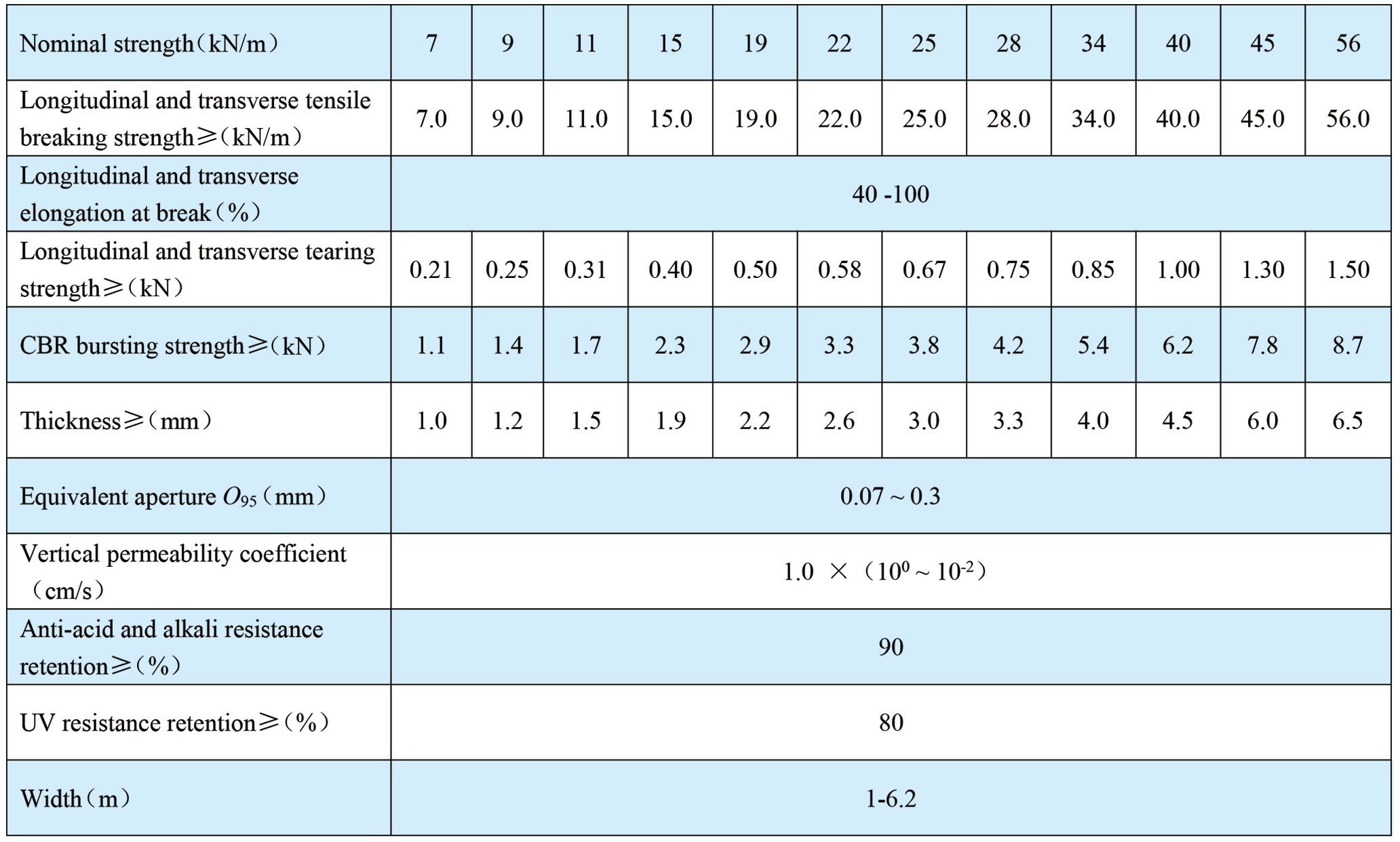

♦ PP Filament Spunbond Needle Punched Nonwoven Geotextile Product Properties

RELATED PRODUCTS